-

Plastic Granulator Machine (19)

-

Waste Plastic Recycling Machine (12)

-

Non Woven Recycling Machine (15)

-

Plastic Film Granulator (12)

-

PE Film Granulator (17)

-

LDPE Film Recycling Machine (10)

-

Plastic Pelletizer Machine (14)

-

PET Pelletizing Machine (8)

-

PVC Pelletizing Machine (11)

-

Plastic Film Pelletizing Machine (13)

LDPE PVC Pelletizing Machine For Waste Plastic Extrusion

| Place of Origin: | China |

| Brand Name: | JIUXIN |

| Model Number: | JXDW-90 |

| Minimum Order Quantity: | 1 |

| Price: | negotiation |

| Packaging Details: | Wooden Package |

| Delivery Time: | 48hrs |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 20 |

|

Detail Information |

|||

| Place of Origin | China | Brand Name | JIUXIN |

|---|---|---|---|

| Model Number | JXDW-90 | Output: | 200m/min+150kg/h |

| Motor Power: | 3kw-7.5kw | Material: | CPE,PE,CPP.PO,PP. EVA,BOPA, PUF,LLDPE |

| Feature: | Cold-extruded | Highlight: | Extrusion PVC Pelletizing Machine,LDPE PVC Pelletizing Machine,LDPE waste plastic extrusion machine |

Product Description

LDPE PVC Pelletizing Machine For Waste Plastic Extrusion

Shredding and Cleaning Plastic:

Two-stage tandem exhaust granulation unit is widely used in the recycling and granulation of various types of plastics such as (LDPE), (HDPE), (PP).

Adopt automatic temperature control, electromagnetic heating, less electricity consumption, no pollution, high degree of automation

The special design of the exhaust port can effectively remove the moisture and volatile gas generated during the material melting process

Adopt advanced low-noise hard tooth surface belt forced lubrication reducer to ensure that the main engine adapts to high-speed continuous operation

Wet pulverization enhances the cleaning effect of waste plastics

The blade is an alloy steel blade that can be re-sharpened for durability.

Sealed design, the casing body is all welded with thick steel plates.

The body adopts a separate design, which is easy to repair and clean;

Double-layer structure, equipped with sound insulation materials, the noise is very low;

The drive equipment adopts the medium-speed motor, low speed, and low energy consumption;

The motor is equipped with an overload protection device and a power supply chain protection system;

Features

PET Bottle Pelletizing Line adopts traditional Relay Electrical Control. Temperature control is Advanced Digital Temperature Control Form PID Adjustment. The main engine and feeding implementation are interlock controlled. The operator panel has a heating and disconnection alarm and main aircraft operation, alarm indication, etc.

PET Bottle Pelletizing Line characteristics:

1.Treated PET bottle flakes are pelletized after washing, and moisture content is within 5%.

2.Three segments and Roots Vacuum Pump, with good exhaust effect.

3.PET Bottle Pelletizer is a Double-screw Extruder with excellent mixing properties, good self-washing, flexible modular combination characteristics. PET Bottle Pelletizing Machine does not require a complex Pre-crystallized drying system, achieving ideal PET viscosity control, low IV decline, adding suitable auxiliaries to achieve increasing adhesion.

| Parameter | |

| Model | JXDW-90 |

| Total Power | 17KW |

| Output | ≈90kg/h |

| Power Supply | AC380V 50Hz TN-S |

| Dimension | 1800x1450x800 |

| Weight | ≈800kg |

| Screw | 90 |

| Reducer | 173 |

| Pelletizing Motor | 0.75W |

| Extrusion Motor | 15KW |

| Inverter | 15KW+1.5KW |

Other benefits

Lower investment cost for a high quality and durable machine;

Low energy consumption with high production output;

Fast machine delivery and installation: JIUXIN produces on an average of 10 sets of plastic machines per month and can deliver the machine faster than most manufacturers.

The regular delivery time of an JIUXIN recycling machine is 30 working days.

Service and support

Overseas installation and training are available;

Machine warranty with spares in stocking and in-time delivery.

JIUXIN compacting and pelletizing system combines function of crushing, compacting, plasticization and pelletizing to one step. Applied in the plastics recycling and pelletizing process. Our system is a reliable and efficient solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

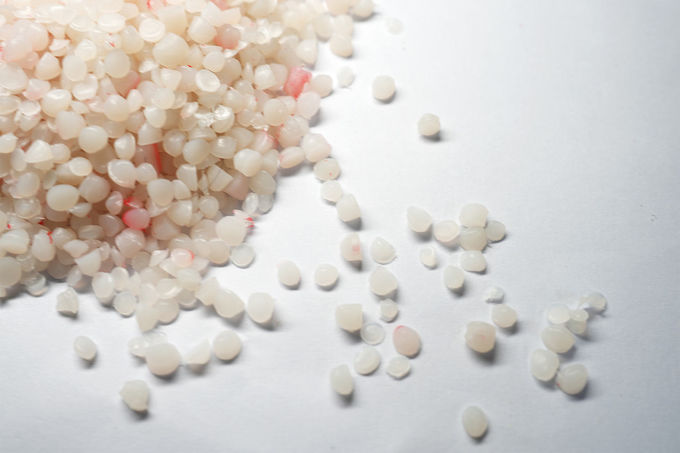

Final productions produced by compacting and pelletizing system are in the form of pellets/granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Feeding:

As standard design, plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor; to handle rolls’ scraps, roll hauling off device is an optional feeding method.

Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor’s room is. Metal detector can be combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal is found in feeding section.