-

Plastic Granulator Machine (19)

-

Waste Plastic Recycling Machine (12)

-

Non Woven Recycling Machine (15)

-

Plastic Film Granulator (12)

-

PE Film Granulator (17)

-

LDPE Film Recycling Machine (10)

-

Plastic Pelletizer Machine (14)

-

PET Pelletizing Machine (8)

-

PVC Pelletizing Machine (11)

-

Plastic Film Pelletizing Machine (13)

Low Speed Waste LDPE Film Recycling Machine For PP Pelletizing

| Place of Origin: | China |

| Brand Name: | JIUXIN |

| Model Number: | JXDW-150 |

| Minimum Order Quantity: | 1 |

| Price: | negotiation |

| Packaging Details: | Wooden Package |

| Delivery Time: | 48hrs |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 20 |

|

Detail Information |

|||

Product Description

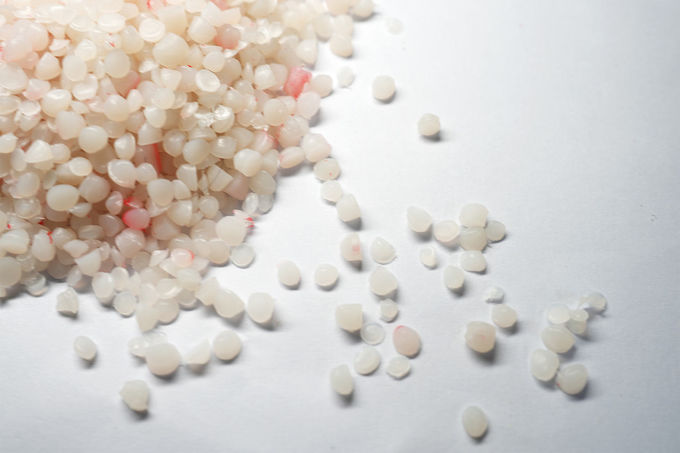

Low Speed Waste LDPE Film Recycling Machine For PP Pelletizing

PET bottle pelletizer granulator machine

Advantages:

1,The granulator can be used continuously and the failure rate is almost zero.Granulation is fast, and the output can reach to 60-120Kg/h.

2,The Pelletizer granulator Machine is suitable for processing the leftovers,rolls, bulk materials and other wastes of various materials such as PE,PP,PO,PVC, EVA,non-woven fabrics, etc. It can be used alone or synchronously with film blowing unit and film casting unit.

3,The granulation process is not heated and without water.The particle size can be controlled to be the same as that of raw materials,and the utilization rate is extremely high.

4,The Pelletizer granulator Machine can be used immediately after startup without preheating.The operation is simple,and it only needs to put the raw material into the feeding port.

5,The Pelletizer granulator Machine is space saving and energy saving,the total power is only 13KW.It is also eco-friendly,smokeless,smelless,low noise and no water during production.

6,The Pelletizer granulator Machine is made of high strength metal accessories,famous brand electronic elements and high precision assembly.We also have strictly QC department to check the Pelletizer granulator Machine before shipping.

Advantages PET bottle pelletizer granulator machine

l Special barrel design can assure better compounding effect so as to improve the problem of black point and chromatism

l Equipped with a force feeder and hydraulic screen changers according to material’s special character, it can get a better capacity and save more power.

l Vacuum or common gas exhaust system, which fascinates getting rid of damp, waste gas, impurity, and ensure a more stable extrusion and more solid pellets.

l Metering feeders are equipped with single screw, twin screw, hollow screw, forced-feeding, system etc., to meet different requirements of feeding, such as powder, pellet, lump and liquid material.

l GEAR TRANSMISSION SYSTEM:

New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and torque get together, which keep it compact, and the key bearings are import.

The computer designs to optimize gear parameters and strengthen safe over measure.

Features

PET Bottle Pelletizing Line adopts traditional Relay Electrical Control. Temperature control is Advanced Digital Temperature Control Form PID Adjustment. The main engine and feeding implementation are interlock controlled. The operator panel has a heating and disconnection alarm and main aircraft operation, alarm indication, etc.

PET Bottle Pelletizing Line characteristics:

1.Treated PET bottle flakes are pelletized after washing, and moisture content is within 5%.

2.Three segments and Roots Vacuum Pump, with good exhaust effect.

3.PET Bottle Pelletizer is a Double-screw Extruder with excellent mixing properties, good self-washing, flexible modular combination characteristics. PET Bottle Pelletizing Machine does not require a complex Pre-crystallized drying system, achieving ideal PET viscosity control, low IV decline, adding suitable auxiliaries to achieve increasing adhesion.

| Parameter | |

| Model | JXDW-150 |

| Total Power | 34KW |

| Output | ≈200kg/h |

| Power Supply | AC380V 50Hz TN-S |

| Dimension | 2450x1050x1500 |

| Weight | ≈1500kg |

| Screw | 150 |

| Reducer | 250 |

| Pelletizing Motor | 1.5W |

| Extrusion Motor | 45KW |

| Inverter | 45KW+1.5KW |